The parts I needed to change, for others' reference, was to have the 'Feed Rate' and 'Flow Rate' equal in the 'Speed' tab of SkeinForge 40.

With all defaults there isn't enough plastic. After calibrating the firmware for the extruder stepper motor, too much plastic is extruded. After evening out those settings in speed, it should be about right, as it was here.

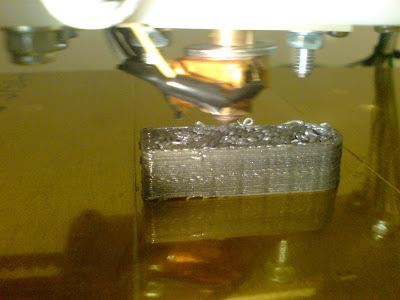

This was running at 20mm/s.

|

| Decent sides, and squiggly lightweight in-fill. |

|

| The top layer of the handle just finishing. |

This was the result:

|

| The finished part, with box generated by orbiting to cool. |

|

| Reverse view. |

|

| A lot more key-shaped than last time, but still not quite right. |

I've just been getting a new spool of filament set up tonight, so that should be live and kicking tomorrow. I'm considering switching the block for cooling steps off completely, but I'll test it with a smaller minimum orbital radius first.

It seems the key design will require some modification anyway, since the triangular hole printed slightly too small, and there isn't much material left around it to stand up to the torque if I cut the hole bigger.

No comments:

Post a Comment